Stop the Finger-Pointing: How Design-Build Delivers Your Custom Home On Budget

📌 Key Takeaways

Budget overruns in custom homes stem from delivery structures that separate design from construction, delay cost feedback, and split accountability between parties.

One Contract Eliminates Liability Shifting: Design-build unifies design and construction under single-source responsibility, replacing finger-pointing with partnership and clear accountability for staying on budget.

Continuous Estimating Prevents Sticker Shock: Real-time pricing feedback during design catches budget issues while adjustments are inexpensive, before drawings lock and construction begins.

Bidding Incentives Drive Low Allowances: Traditional competitive bidding encourages artificially low allowance numbers to win contracts, creating predictable budget drift when realistic selections exceed placeholder amounts.

Nine Habits Protect Any Budget: Written allowances schedules, budget checkpoints at design milestones, early sitework analysis, and shared scope logs prevent surprises regardless of delivery method.

Hill Country Variables Amplify Risk: Rock, slope, drainage, HOA requirements, and permitting timelines create cost uncertainty that integrated teams surface early rather than discover during construction.

Change the structure, change the outcome—unified teams force necessary budget conversations when course corrections still cost hours, not thousands.

Homeowners planning luxury custom builds in the Texas Hill Country will gain a decision framework for evaluating builders and delivery methods, preparing them for the detailed comparison and question checklist that follows.

It's 6:00 PM on a Sunday evening. The spreadsheet is open, columns filled with line items labeled "allowances." Granite countertops—are they included or not? The numbers blur together. Somewhere between the architect's vision and the builder's estimate, the budget drifted. Now everyone points fingers.

This scenario plays out in custom home projects across the Texas Hill Country more often than it should. The dream of a lakefront retreat or a hilltop sanctuary becomes overshadowed by cost overruns, surprise invoices, and tense conversations about who is responsible for what.

Here's the truth that most homeowners discover too late: finger-pointing isn't a personality problem. It's a structural problem—one built into how the project was set up from day one.

This article breaks down why budgets spiral in traditional construction delivery, how design-build creates a different outcome, and what you can do right now to protect your investment. You'll walk away with a practical framework: a comparison of delivery methods, a budget-control checklist, and pointed questions to ask any builder before signing a contract.

When the Budget Blows Up, the Blame Starts

Stand on an empty lot in the summer heat, trying to visualize where the porch should catch the evening breeze. It's exciting. It's also the moment when budget risk begins—though most homeowners won't realize it until months later.

The problem isn't ambition. It's the gap between design decisions and cost feedback.

In many custom home projects, the design phase and the construction phase operate as separate worlds. An architect creates drawings. Those drawings go out for bids. A builder wins the job. Then reality hits: the design costs more than expected, selections weren't specified clearly, and site conditions demand changes nobody anticipated.

Who's responsible? The architect says the builder should have flagged the issue. The builder says the drawings were incomplete. The homeowner stands in the middle, watching the budget climb.

This isn't bad luck. It's the predictable result of a delivery method that separates accountability.

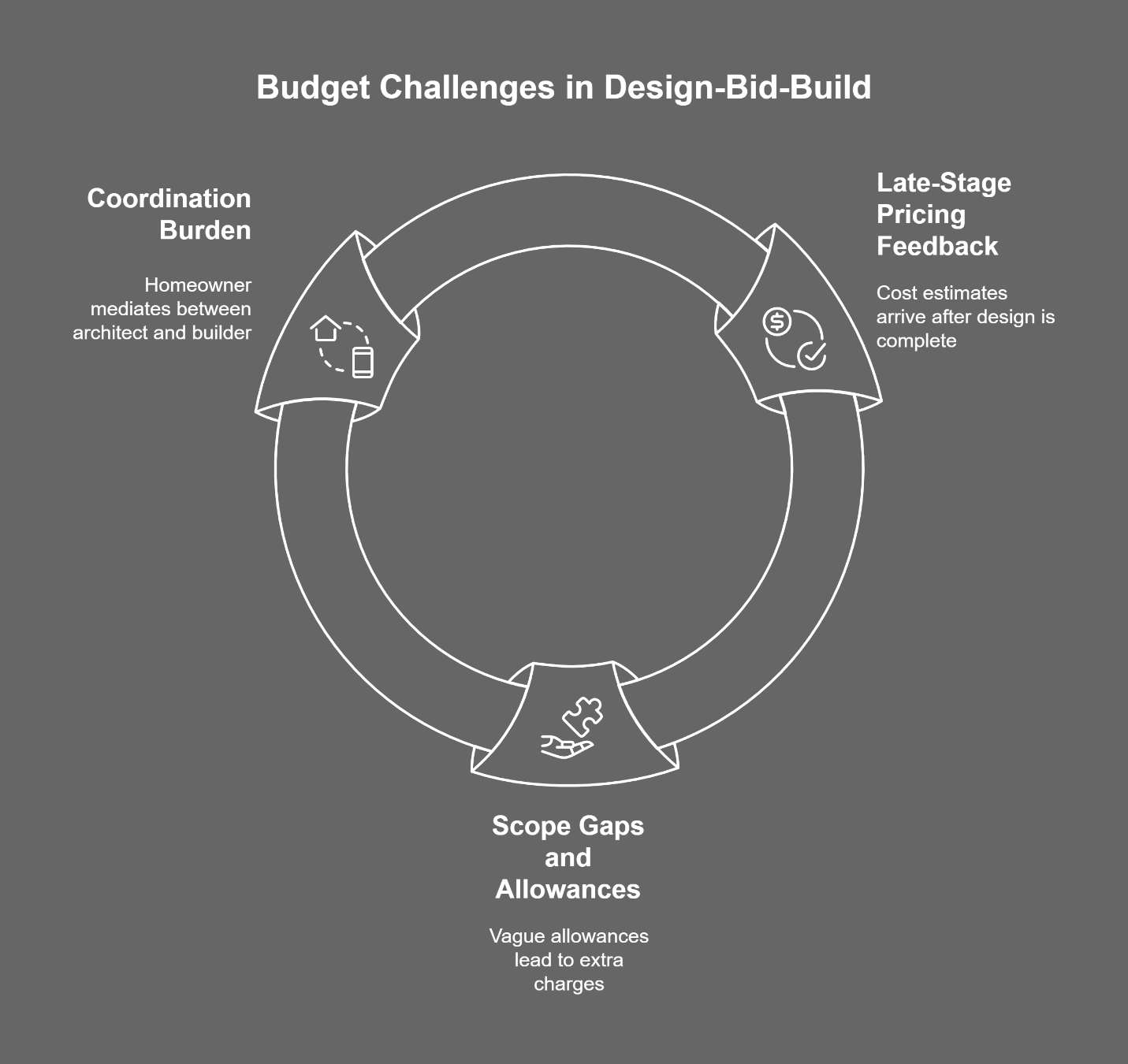

Why Custom Home Budgets Drift in Traditional Design-Bid-Build

Traditional design-bid-build creates three structural budget failure points. The traditional approach to building a custom home is called design-bid-build (DBB). It works like this: you hire an architect to design the home, then solicit bids from builders, then select a contractor to construct what the architect drew.[1]

On paper, it sounds logical. In practice, it creates three structural problems that drive budget overruns.

Problem 1: Late-Stage Pricing Feedback

In design-bid-build, detailed cost estimates typically arrive after design is substantially complete. By the time you learn what the home actually costs to build, the drawings are done. If the number exceeds your budget, you face an uncomfortable choice: cut scope (value engineering), increase the budget, or start over.

This late-stage sticker shock is one of the most common sources of frustration in custom home projects.

Problem 2: Scope Gaps and Allowances

Before going further, two terms matter here:

Allowances: A placeholder dollar amount set aside for a category of work or a finish selection that isn't finalized yet—for example, lighting, plumbing fixtures, flooring, or appliances. While allowances are used in both delivery methods, the risk in traditional bidding comes when these numbers are set low to win a bid, rather than based on realistic client expectations. If actual selections cost more than the allowance, the budget increases.

Change orders: Formal changes to the original scope, price, and/or schedule after the contract is signed. Some changes are owner-driven ("adding a door"), while others come from discoveries (site conditions) or omissions. The key is having a clear process for pricing, approvals, and documentation.

When the architect and builder work under separate contracts, assumptions don't always align. The drawings might show a "tile backsplash" without specifying the tile. The builder includes an allowance—a placeholder dollar amount—for that selection. If the homeowner chooses tile that costs more than the allowance, the difference becomes an extra charge.

Allowances aren't inherently bad. But when they're vague, numerous, or buried in contract language, they become a mechanism for budget drift. What looked like a fixed price turns out to be a floor, not a ceiling.

Problem 3: The Coordination Burden Falls on the Homeowner

With two separate contracts—one with the architect, one with the builder—the homeowner becomes the de facto project manager. When disputes arise about whether something was "in the plans" or "included in the bid," the homeowner must mediate.

This coordination burden adds stress and creates fertile ground for liability shifting. Neither party has full accountability for the outcome. Both can point to the other's contract.

The American Institute of Architects describes design-bid-build as a sequential process where the owner holds separate agreements with the designer and contractor.[2] That structure, while familiar, places the integration risk squarely on the owner.

Design-Build, Explained in One Sentence

Design-build means one entity holds one contract and takes unified responsibility for both design and construction.

That's it. One team. One agreement. One point of accountability.

The Design-Build Institute of America defines design-build as a project delivery method where a single entity—the design-build team—works under a single contract with the project owner to provide design and construction services.[3]

But design-build isn't just paperwork. It's a collaborative mindset. The designer and builder work together from the start, which means construction expertise informs the design before drawings are finalized—not after.

Some firms describe this as single-source responsibility, integrated design and construction, or turnkey custom building. The labels vary. The principle remains: unified accountability changes how decisions get made and how budgets get managed.

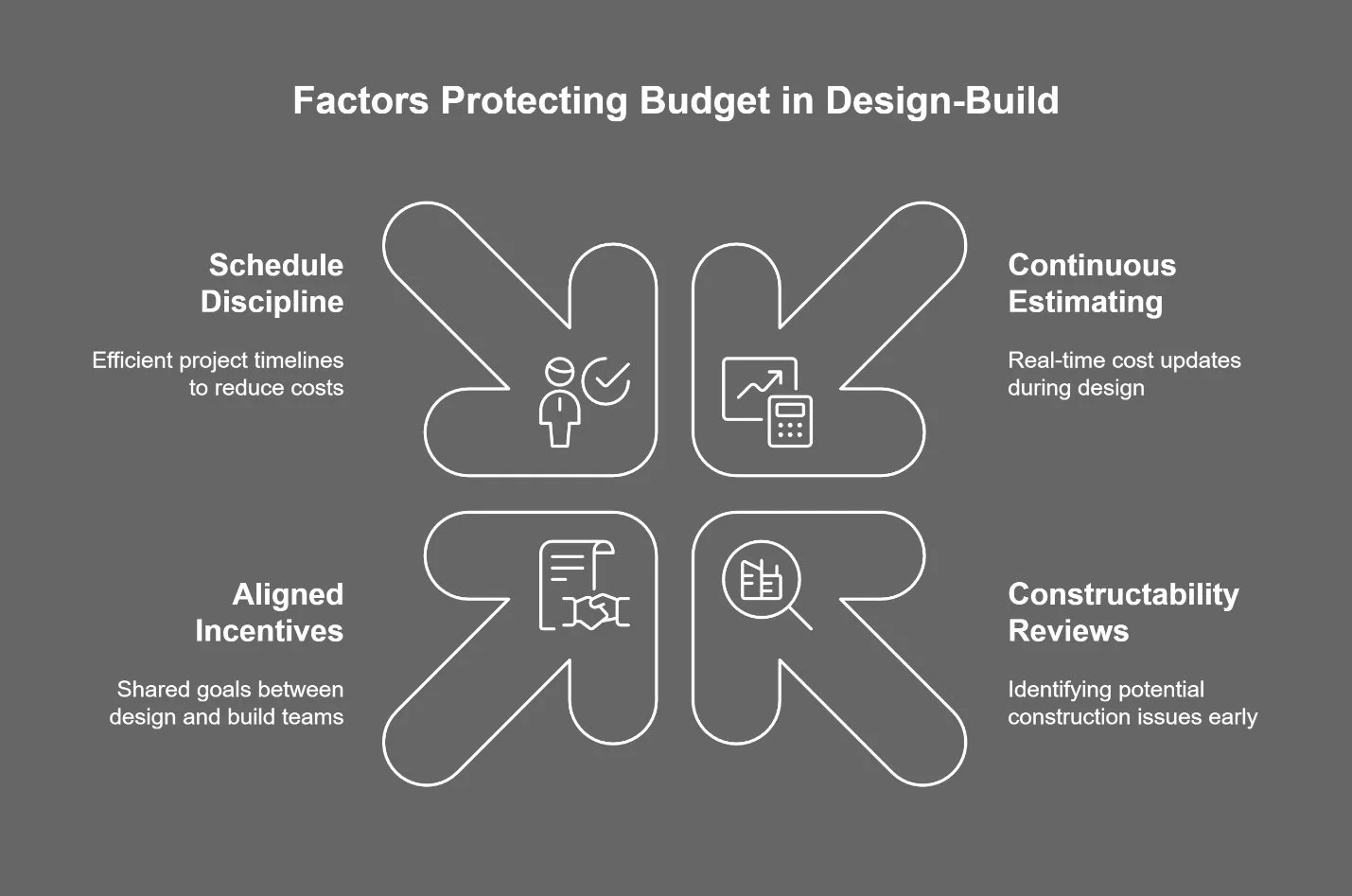

Before vs. After: What Changes with Design-Build (and Why It Protects the Budget)

The shift from design-bid-build to design-build isn't cosmetic. It changes four specific behaviors that directly affect whether your project stays on budget.

Behavior 1: Continuous Estimating During Design

Decisions and cost are managed together. In design-build, the builder participates in the design process. That means cost estimates evolve alongside the drawings. If a design decision pushes the budget, you find out immediately—not after the plans are "done."

This real-time feedback loop allows for course corrections while options are still open. Want that wall of windows facing the lake? The team can price it now, while there's still time to adjust the roofline or simplify the back elevation to compensate.

This approach reduces the "design it first, price it later" trap.

Behavior 2: Constructability Reviews Reduce Surprises

Builders see things architects sometimes miss—not because architects lack skill, but because their focus is different. A builder might notice that a cantilevered deck will require expensive structural steel, or that a roofline detail will be difficult to waterproof in the Hill Country's intense rain events.

When the builder is at the table during design, these constructability issues surface early. Problems get solved on paper, where changes cost hours. Not in the field, where changes cost thousands.

Behavior 3: Aligned Incentives Eliminate the "Design It First, Price It Later" Trap

In design-bid-build, the architect's job is to fulfill your vision. The builder's job is to build what the architect drew. Neither party is explicitly responsible for keeping the project on budget—that burden falls to the homeowner.

Design-build aligns incentives differently. The design-build firm succeeds when the project meets the homeowner's goals within the agreed budget. That shared stake changes conversations. Instead of defending separate scopes, the team collaborates to find solutions that work architecturally, structurally, and financially.

Behavior 4: Schedule Discipline Reduces Financing Exposure

A faster, more predictable build schedule isn't just convenient—it can save money. Extended construction schedules mathematically increase interest and holding costs. Actual impacts vary by loan structure, market conditions, and project specifics.

Design-build's integrated approach often compresses timelines by overlapping design and preconstruction activities. When teams don't overcommit—when they take on only the projects they can manage with daily on-site attention—schedule drift becomes less likely.

Riverbend Homes, a second-generation family-owned builder serving the Texas Hill Country since 1996, emphasizes this discipline: manageable project loads mean every home gets the supervision it needs, which translates to faster completion and reduced interest exposure.

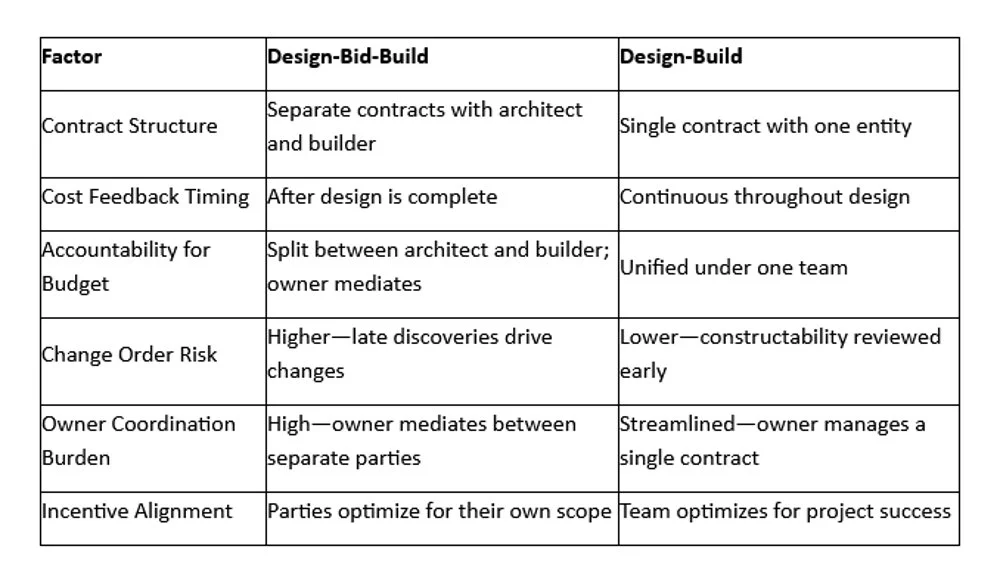

Comparison Table: Design-Bid-Build vs. Design-Build

This table simplifies a nuanced reality. Both delivery methods can work well with the right team and the right project. But for homeowners whose primary concern is budget certainty and reduced stress, design-build's structure offers meaningful advantages.

The Design-Build Accountability Flowchart

Understanding where budget drift typically enters—and how design-build closes those gaps—helps you evaluate any firm's process, regardless of what they call their delivery method.

In a traditional bid-build process, budget risk accumulates at predictable points:

Design proceeds without detailed cost input

Allowances are set based on assumptions, not selections

Bids arrive after design is "locked"

Site conditions (rock, slope, utilities) surface during construction

Selections run over allowances; change orders multiply

Disputes arise about what was "included"

Owner mediates between architect and builder

In a design-build process, each gap has a corresponding control:

Builder participates in design; estimates update in real time

Allowances are scheduled with selection deadlines and clear overage policies

Budget checkpoints occur at each design milestone

Site analysis happens early; costs are incorporated before pricing finalizes

Selections are tracked in a shared scope and budget log

One contract defines inclusions and exclusions

One team owns the outcome; no liability disputes

The On-Budget Playbook: 9 Habits That Prevent Surprise Costs

Delivery method matters, but process discipline matters just as much. Whether you choose design-build or another approach, these nine habits help homeowners maintain budget control.

Habit 1: Set a budget range early and define must-haves versus nice-to-haves.

Before design begins, establish a realistic range—not a single number. Identify which features are non-negotiable (the view-facing great room, the primary suite on the main floor) and which are flexible (the outdoor kitchen, the third garage bay). This clarity gives the design team room to optimize.

Habit 2: Require budget checkpoints at each design milestone.

Don't wait until drawings are complete to learn what the home costs. Insist on updated estimates at schematic design, design development, and construction documents. If the number drifts, you'll know while changes are still affordable.

Habit 3: Demand a written allowances schedule and a selection timeline.

Allowances should be specific: not just "flooring allowance—$15,000" but "engineered hardwood, 1,800 SF living areas, $8.33/SF installed." Pair each allowance with a selection deadline so you're not rushed into decisions that blow the budget.

Habit 4: Insist on a clear change-order policy.

Before signing, understand how changes are priced, documented, and approved. A good policy specifies markup percentages, requires written authorization before work proceeds, and provides itemized breakdowns. No surprises.

Habit 5: Surface sitework risks early.

In the Texas Hill Country, what lies beneath the surface can dramatically affect cost. Rock excavation, slope stabilization, drainage solutions, utility extensions, septic systems—these aren't optional. Ask for a site analysis before finalizing the budget. Firms experienced in building custom homes in the Texas Hill Country know how to assess these variables and incorporate them into early estimates.

Habit 6: Lock long-lead selections intentionally to avoid rush premiums.

Custom windows, imported tile, specialty appliances—these items have lead times measured in weeks or months. Identify long-lead items early and make selections on schedule. Last-minute substitutions often cost more and compromise the design intent.

Habit 7: Confirm permitting and HOA workflow and who owns it.

Permitting timelines and HOA approval processes vary across the Hill Country. Some communities require architectural review that adds weeks. Some jurisdictions have inspection backlogs. Clarify who manages these workflows and build realistic timelines. For more on this, see how design-build firms handle permits and regulations.

Habit 8: Ask about project load and supervision.

A builder juggling too many projects can't give yours the attention it needs. Ask how many homes the firm has under construction, who will be on-site daily, and how communication is handled. Consistent supervision prevents the small issues that become expensive problems.

Habit 9: Track scope decisions in one shared scope and budget log.

Every decision—confirmed selections, approved changes, allowance adjustments—should live in one document that both you and the builder update. This shared log prevents "I thought that was included" disputes. It's the single source of truth.

For a deeper look at how these milestones unfold, explore key milestones in your custom home journey.

Questions to Ask a Design-Build Firm (So Accountability Is Real, Not Marketing)

Every builder claims to be different. These questions help you assess whether a firm's process matches its promises.

On Cost Feedback and Estimating:

How often do you update cost estimates during design—and at what milestones?

What's included in your base scope, and what's typically excluded?

Can you walk me through a recent project where the initial estimate changed? What drove the variance?

On Allowances and Selections:

How are allowances structured in your contracts? Are they line-item specific or lump-sum categories?

What happens if a selection exceeds the allowance—is there markup on the overage?

What's your typical selection timeline, and how do you help homeowners stay on track?

On Change Orders and Documentation:

How are change orders priced, and what documentation do you provide?

Do you require written approval before change-order work begins?

How do you handle disputes about whether something was "in scope"?

On Supervision and Communication:

How many projects do you have under construction right now?

Who will be my day-to-day point of contact, and how often will they be on-site?

How do you communicate progress—weekly meetings, a project portal, phone calls?

On Site and Regulatory Issues:

How do you assess site conditions (rock, slope, drainage, utilities) before finalizing the budget?

Who manages permitting and HOA approvals, and what timeline should we expect?

Have you built in our specific community or area before? What did you learn?

A firm that answers these questions with specifics—not generalities—demonstrates the process discipline that keeps projects on budget.

Texas Hill Country Reality Check: Why Delivery Method Matters Even More Here

Building in the Texas Hill Country isn't like building in a flat suburban subdivision. The terrain, the regulations, and the lifestyle expectations create variables that amplify budget risk if not addressed early.

Topography and geology matter. Limestone shelves hide beneath thin topsoil. Slopes require engineered foundations. Drainage patterns affect where you can place the home and how stormwater moves off the site. A builder who doesn't walk the lot before pricing is guessing—and guesses become change orders.

HOAs and permitting vary by community. Some neighborhoods around Lake Travis and Horseshoe Bay have architectural review committees with specific aesthetic requirements. Others have minimal oversight. Permitting timelines in Burnet County differ from Travis County. A design-build firm with deep local experience—one that's been building in Spicewood and surrounding areas for decades—knows these nuances and builds them into the schedule and budget from the start.

Waterfront and view sites demand integrated thinking. The whole point of building on Lake LBJ or overlooking the hills is to capture the setting. Orienting the home correctly, sizing windows for the view, managing solar heat gain—these decisions affect both design and construction cost. When the designer and builder collaborate from day one, the home can maximize its site without budget surprises.

Integrated teams make better decisions faster. And in a market where project complexity is the norm, that integration is especially valuable.

When Design-Build May Not Be the Best Fit

Transparency means acknowledging when a recommendation doesn't apply. Design-build isn't the right choice for every homeowner.

If your goal is to shop a completed design for the lowest bid, design-build may not match your approach. The model assumes collaboration from the start. If you've already invested in architectural plans and want competitive pricing from multiple builders, a traditional bid process may serve you better—though you'll bear the coordination risk that comes with it.

If you want maximum control over every subcontractor selection, design-build's integrated model may feel constraining. Some homeowners prefer to choose their own tile installer or cabinet shop. Design-build firms typically manage their own trade networks to maintain quality and schedule control. That trade-off isn't right for everyone.

If budget is secondary to design ambition, and you're willing to adjust the budget to achieve a specific architectural vision regardless of cost, the continuous pricing feedback of design-build may feel like a constraint rather than a benefit. Some projects prioritize design purity over cost certainty.

For homeowners who value budget control, reduced stress, and unified accountability, design-build generally offers a better fit. But fit depends on your priorities.

Conclusion: From Finger-Pointing to a Home Built with Confidence

The Sunday evening spreadsheet doesn't have to end in confusion. The empty lot doesn't have to become a battlefield.

Budget overruns in custom homes aren't inevitable. They're the predictable result of delivery structures that separate design from construction, delay cost feedback, and diffuse accountability. Change the structure, and you change the outcome.

Design-build creates one point of responsibility. It forces pricing conversations during design, when course corrections are still possible. It aligns the team's incentives with your goals. And it replaces finger-pointing with partnership.

The checklist and questions in this article give you a framework—not just for evaluating design-build firms, but for assessing any builder's process discipline. Use them. The homeowners who stay on budget aren't luckier. They're better prepared.

Ready to discuss your lot, your vision, and a realistic budget path?

Schedule a Discovery Call with Riverbend Homes:

Phone: (512) 468-0240

Email: ben@riverbend-homes.com

Contact Riverbend Homes →

Explore more:

Frequently Asked Questions

Is design-build more expensive than design-bid-build?

Not necessarily. Design-build eliminates the competitive bidding phase, which some assume means higher prices. In practice, reduced change orders, shorter schedules, and fewer coordination failures often result in lower total project costs. The right comparison isn't the initial contract price—it's the final cost after all changes. Total cost depends on scope, site conditions, and selections.[1][4]

How does design-build control costs during design?

By having the builder at the table while design decisions are being made. Every material choice, structural decision, and finish selection gets priced in real time. If something pushes the budget, the team can adjust immediately rather than discovering the problem after bids come in. This continuous estimating allows tradeoffs to be made before construction starts, when changes are typically less disruptive.[1][4]

What causes change orders in custom homes?

Common causes include incomplete drawings, unforeseen site conditions, homeowner-requested changes, allowance overruns, and code or regulatory requirements discovered during construction. Design-build reduces (but doesn't eliminate) change orders by surfacing issues earlier and documenting decisions more thoroughly. The frequency and impact depend on the clarity of scope and the change-order process.

What are allowances and how do they affect the budget?

An allowance is a placeholder dollar amount for an item that hasn't been selected yet—like lighting fixtures or countertop material. If your final selection costs more than the allowance, you pay the difference (often plus markup). If it costs less, you receive a credit. Vague or unrealistic allowances are a leading cause of budget surprises. Allowances are most stable when documented clearly and paired with an early selections schedule.

Can I use my own architect with a design-build firm?

Some design-build firms work with outside architects; others use in-house design teams or preferred architect partners. The key question is how well the architect and builder collaborate. If you have an architect you trust, ask prospective design-build firms whether they're open to that arrangement and how they've handled it in the past. The key is preserving clear accountability and continuous pricing feedback if outside parties are involved.[2]

How early can I get an accurate estimate for my custom home?

With design-build, preliminary estimates can come early—sometimes before schematic design is complete. These initial numbers refine as design progresses. By the time construction documents are finished, the estimate should be highly accurate. In design-bid-build, accurate estimates typically don't arrive until bidding, which happens after design. Early estimates can be developed once scope and major drivers (size, complexity, site constraints, and key selections) are defined. Accuracy typically improves as selections and documentation become more specific.[3][4]

What's the difference between a fixed-price contract and a cost-plus contract?

A fixed-price (or stipulated-sum) contract sets a total price for defined scope. A cost-plus contract reimburses actual costs plus a fee or percentage. Both can work in design-build. Fixed-price offers more certainty; cost-plus offers more flexibility. The right choice depends on how well-defined the scope is and how much risk you're willing to share.

How do I know if a design-build firm is legitimate?

Look for longevity, local references, and process transparency. Ask how long they've been in business, how many homes they've completed in your area, and whether they can connect you with recent clients. Review their contracts and change-order policies before signing. A legitimate firm welcomes scrutiny.

References

[1] Design-Build Institute of America. "What is Design-Build?" https://dbia.org/what-is-design-build/

[2] American Institute of Architects. "A Primer on Project Delivery Terms." https://www.aia.org/resource-center/primer-project-delivery-terms

[3] Trimble. "Design-Bid-Build." https://www.trimble.com/blog/construction/en-US/article/project-management/project-delivery-methods/design-bid-build

[4] Procore. "Design-Build vs Design-Bid-Build." https://www.procore.com/library/design-build-vs-design-bid-build

Disclaimer: This article is for educational purposes only. Costs, schedules, and requirements vary by site, jurisdiction, and project scope. For guidance specific to your property and goals, consult qualified professionals.

Our Editorial Process: Our expert team uses AI tools to help organize and structure our content. All information is reviewed and refined by humans on our Insights Team to ensure accuracy and clarity.

About the Author: Riverbend Homes Group, LLC is a custom home builder based in Spicewood, serving the Texas Hill Country, including Lake Travis, Lake LBJ, Bee Cave, and Horseshoe Bay. The Insights Team distills lessons from project management, selections, and homeowner education to help you plan and build with confidence.