The 'Possibility Mindset' in Custom Building: How to Build What Others Say is Impossible

📌 Key Takeaways

"Impossible" in custom building typically means untested against real constraints—site conditions, rules, infrastructure, and budget—not genuinely unbuildable.

Site Walks Reveal Hidden Realities: Walking your property uncovers drainage patterns, rock formations, and view opportunities that photos cannot capture, preventing costly mid-build surprises.

Design-Budget Feedback Loops Save Dreams: Keeping design and budget in constant conversation—with defined allowances and identified cost drivers—prevents falling in love with unaffordable plans.

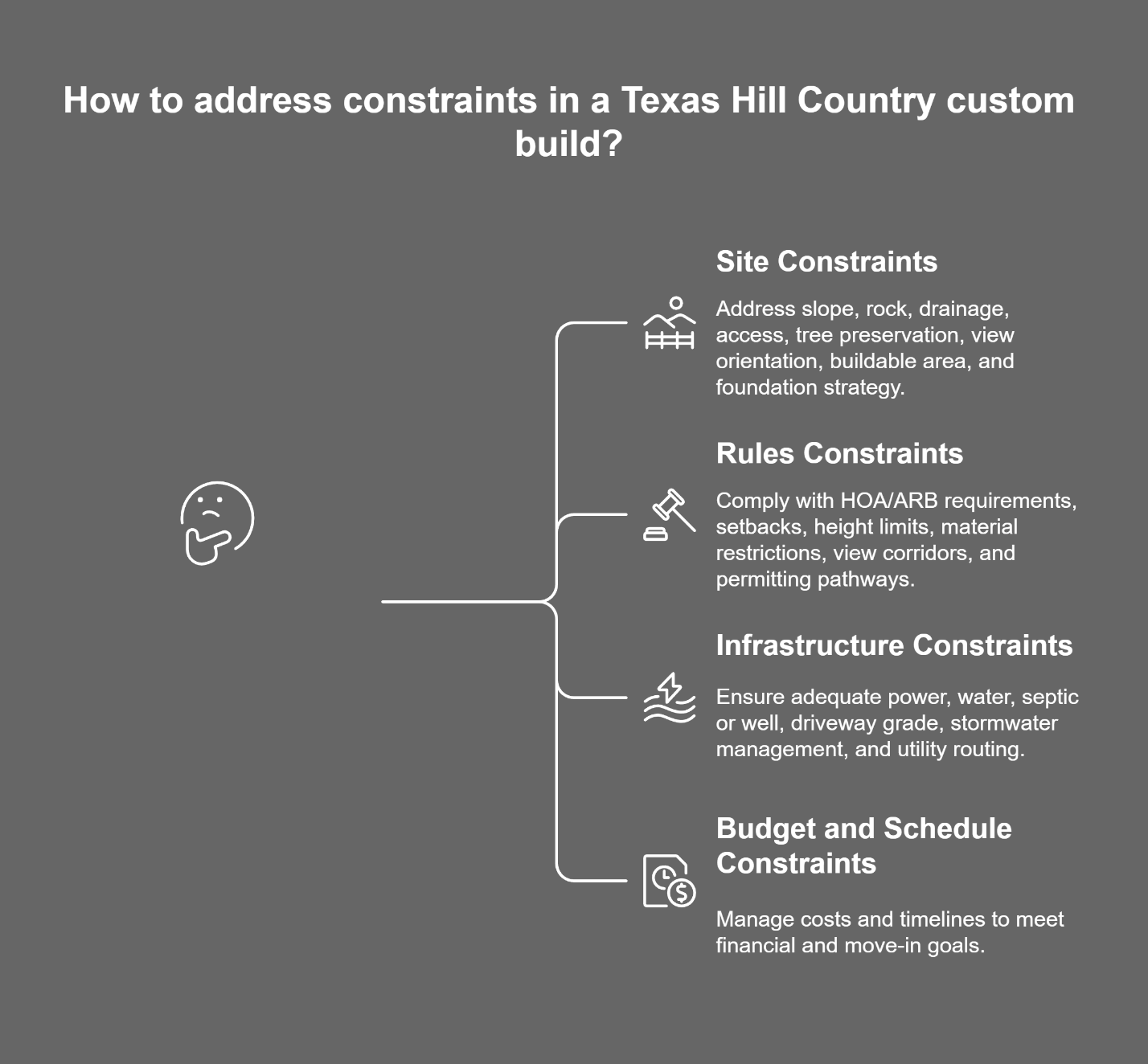

Four Constraint Buckets Frame Decisions: Testing ideas against site, rules, infrastructure, and budget transforms vague "no" responses into specific, solvable engineering or design adjustments.

Lock Early to Prevent Expensive Redesigns: Finalizing siting, floor elevation, structural concept, and window strategy before construction prevents cascading changes that unravel engineering and trades.

Pricing Without Lot Walks Signals Risk: Builders who quote without standing on your property are guessing; vague allowances and weak oversight compound budget disasters.

Tested constraints convert bold visions into buildable plans.

Families planning custom homes on challenging Texas Hill Country lots will gain a feasibility framework here, preparing them for the detailed checklist and process guide that follows.

You've heard the word before. Impossible.

Maybe it came during a phone call with a builder who barely glanced at your lot photos. Maybe it arrived in a vague email after you described the hillside view you wanted to capture. The kitchen that opens to the canyon. The roofline that follows the ridge.

That single word can stop a dream cold—especially when you've already imagined your family gathering in that space for decades to come.

But here's what most builders won't tell you: "impossible" rarely means what it sounds like. In custom home building, it usually means the idea hasn't been tested yet. It hasn't been walked, measured, engineered, or priced against real constraints. And that's a very different thing.

The Possibility Mindset isn't about wishful thinking. It's about replacing assumptions with answers—so you can turn a bold vision into a buildable plan.

What "Impossible" Usually Means in Custom Home Building

When a builder says "that can't be done," they're often saying something else entirely:

Unpriced: They haven't run the numbers against your actual site conditions.

Unengineered: No one has checked whether the slope, soil, or setbacks allow for your concept.

Unconstrained: The idea hasn't been tested against real inputs—lot, rules, utilities, and budget.

These aren't dead ends. They're unanswered questions.

Four Buckets of Constraints

Every custom build in the Texas Hill Country faces some combination of these:

Site: Slope, rock, drainage, access, tree preservation, view orientation, buildable area, and foundation strategy

Rules: HOA/ARB requirements, setbacks, height limits, material restrictions, view corridors, and permitting pathways

Infrastructure: Power, water, septic or well, driveway grade, stormwater management, and utility routing

Budget and schedule: What you can realistically spend—and when you need to move in

The follow-up questions that turn "no" into clarity sound like this: Which constraint is blocking us? Is it solvable with engineering? Does it require a design adjustment? What does it cost to address?

Experienced Texas Hill Country custom home builders don't just identify obstacles—they translate them into decisions you can actually make.

The Possibility Mindset: Turning Constraints Into a Buildable Plan

The Possibility Mindset is a process, not a personality trait. It works because it front-loads reality instead of discovering it mid-build.

Start With the Lot

A real site walk beats assumptions every time. Walking your property reveals things photos can't: how water moves during a storm, where the rock shelf sits, which trees frame the view you actually want. In Spicewood and across the Hill Country, terrain varies wildly—sometimes within a single acre.

Hill Country examples where feasibility often changes the plan:

A steep grade that demands stepped foundations or retaining solutions

Rock that changes excavation assumptions and utility trenching plans

Drainage patterns that affect driveway placement and finished floor elevation

Lakefront adjacency where flood hazard checks and setbacks shape siting decisions (use the FEMA Flood Map Service Center as a starting point for general flood hazard lookup)

Design and Budget Feedback Loops

This is where most dreams get saved. Instead of designing in a vacuum and pricing later (a recipe for heartbreak), the Possibility Mindset keeps design and budget in constant conversation. Allowances get defined early. Cost drivers—structural complexity, retaining walls, glazing, sitework—get identified before you fall in love with a plan you can't afford.

Key terms to handle plainly:

Allowances: budget placeholders for items not selected yet (finishes, fixtures). The risk isn't the concept—it's vagueness and lack of guardrails.

Change orders: formal scope changes after decisions are made; they can be legitimate, but should be governed by clear rules.

Bid set: a sufficiently detailed plan package that trades can price consistently (not a loose concept set).

Understanding pricing models: Fixed-price contracts generally aim to establish a set total based on a defined scope, offering predictability when details are clear early, though they may still include escalation clauses for volatile material costs. Cost-plus arrangements reimburse actual costs plus a builder's fee, offering flexibility but demanding strong transparency and strict controls regarding allowances and change orders. Complex builds often utilize hybrid contracts—stabilizing costs for structural/sitework while using allowances for finishes to maintain design flexibility. The more complex the site or design, the more important it becomes to define scope tightly before "locking" numbers.

If you want to understand how feasibility flows into real pricing and a buildable scope, see our building process.

Engineering, Permitting, and Trade Input at the Right Time

Feasibility isn't a single meeting. It's a sequence. Structural concepts need engineering review. Septic systems need site evaluations (the Texas Commission on Environmental Quality regulates on-site sewage facilities across the state). HOAs and architectural review boards—especially in communities like Horseshoe Bay—have approval timelines that affect your schedule.

On challenging sites, the sequence often matters as much as the solution. Structural concepts, drainage approach, and utility plans should inform design, not chase it.

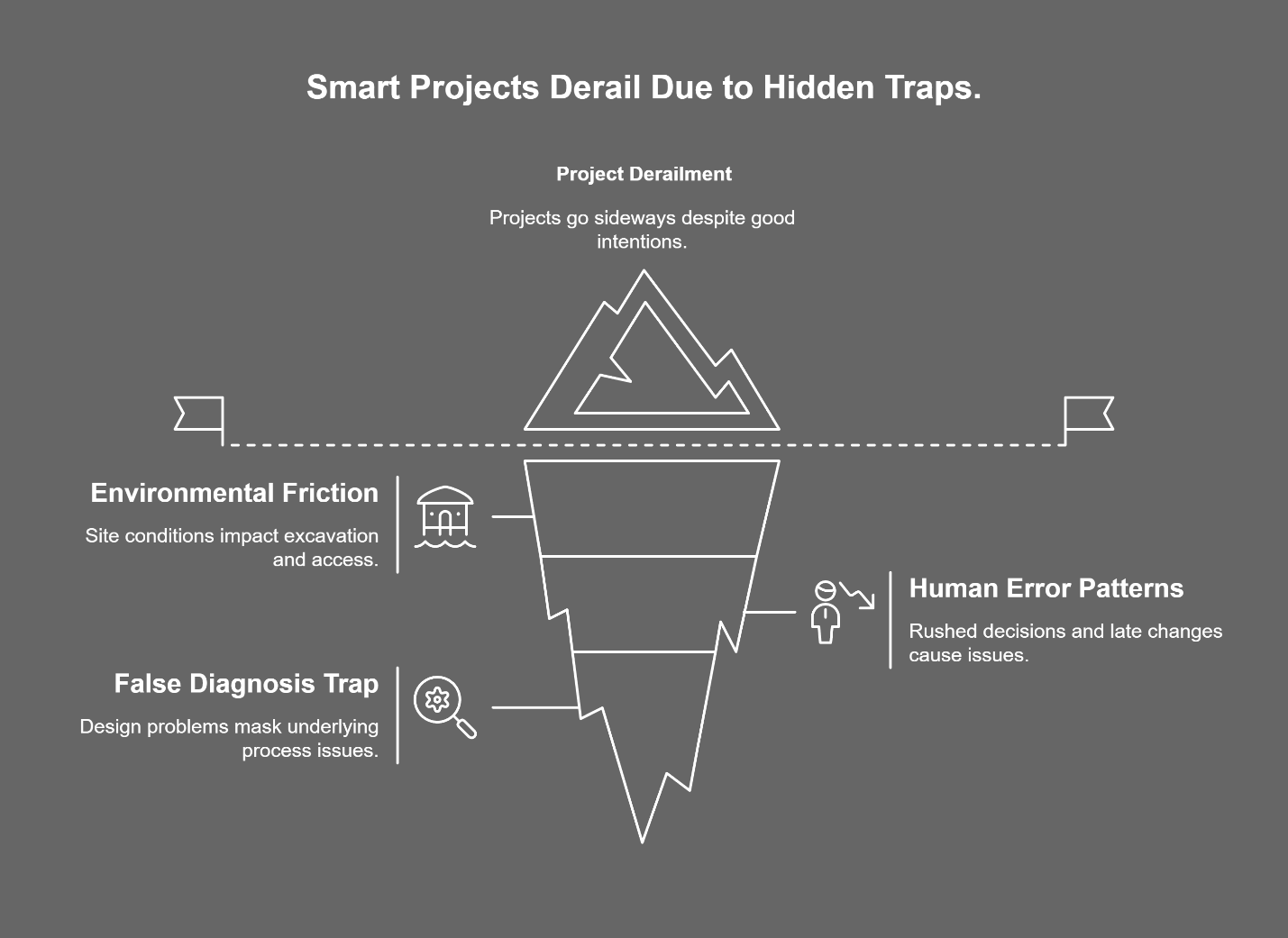

Diagnostics and Digressions: Why Smart Projects Still Go Sideways

Even with good intentions, builds can derail. Here's where the traps hide:

Environmental friction. A Lake Travis lot might sit in a flood hazard zone. Rock formations can double excavation costs. Steep driveways can limit fire truck access—and insurance options. On sloped or rocky ground, civil/sitework assumptions can be fragile. Drainage and access aren't "later problems"—they're feasibility inputs.

Human error patterns. Falling in love with renderings before feasibility. Approving a scope, then requesting "small changes" that ripple through structure and budget. Assuming allowances will cover your taste without verifying the numbers. Late changes aren't automatically wrong, but they should be evaluated with cost and schedule visibility.

The false diagnosis trap. Sometimes what looks like a design problem is actually a process problem—unclear scope, vague allowance language, or a builder who priced without walking the lot. Redesigning won't fix a broken process. If the real issue is vague allowances, incomplete trade input, or missing site data, more design alone won't solve it.

The Vision Feasibility Checklist

Before you commit to drawings or deposits, run your vision through these checkpoints:

In-Article Checklist

Clarify your vision. Write it in one sentence. Then list your top three non-negotiables—the features you won't sacrifice.

Assess lot realities. Slope, rock, drainage, access, view orientation, and trees worth saving. If you haven't walked the property with a builder, you haven't started feasibility.

Understand the rules. HOA and architectural review board requirements. Setbacks, height limits, approved materials, view corridor restrictions. Rules can be design-shaping; confirm constraints early rather than redesign later.

Confirm infrastructure. Power availability. Water source. Septic or well requirements. Driveway grade and stormwater management. Utility availability and routing can move the "best" homesite and influence the budget.

Set a budget band. Not a single number—a range. Identify the biggest cost drivers: structural complexity, civil and sitework, glazing, retaining walls. A range reduces false precision.

Vet the process. Insist on a lot walk before pricing. Demand written scope with clear allowances and change-order rules. The goal isn't a low number—it's a durable number.

Lock early decisions. Siting, finished floor elevation, structural concept, and window strategy. These prevent expensive redesigns later and tend to cascade into many downstream choices.

Red Flags: When "Yes" Is Actually the Dangerous Answer

A builder who says "yes" to everything without caveats isn't being optimistic. They're being careless.

Watch for:

Pricing without a lot walk. If they haven't stood on your property, they're guessing. Without site realities, numbers can be ungrounded.

Vague allowance and change-order language. "We'll figure it out" is how budgets explode. If allowances aren't defined and change-order rules are unclear, cost control becomes reactive.

Weak on-site oversight. Ask how many projects they run simultaneously—and how often someone is physically present on your build. Complex builds require consistent supervision and predictable updates.

How Riverbend Makes "Possible" Predictable

Riverbend Homes limits the number of projects in progress at any time. That's not a limitation—it's a commitment. It means daily on-site presence, not weekly check-ins. It means problems get caught early, when they're cheap to fix.

The process—Discover, Design and Budget, Build—creates milestones where decisions lock in before costs escalate. Communication happens on a predictable cadence, not when something goes wrong.

One client put it simply: "They took what others said was impossible, and made it possible." Another described the experience this way: they won't leave you hanging and wondering what's next.

That's what the Possibility Mindset looks like in practice. Not magic—process. Not promises—proof points.

Learn more about Riverbend Homes or read client reviews from families who brought bold ideas to the table.

Next Step: Bring Your Vision—We'll Help You Test It

Have a bold idea—or a challenging lot? Schedule a discovery meeting and we'll help you test feasibility early, before you spend months on drawings.

What to bring:

Photos or a description of your lot (address helps)

Inspiration images, Pinterest boards, or magazine clippings

Your budget range (even a rough band is useful)

Your timeline goals

Frequently Asked Questions

When a builder says "that can't be done," what does that usually mean?

It usually means the idea hasn't been tested against real constraints—site, rules, infrastructure, or budget. Feasibility inputs are missing. A thorough feasibility process often reveals options.

How early should I involve a builder or engineer for a challenging Hill Country lot?

Before you finalize a purchase if possible. A lot walk with an experienced builder can surface deal-breakers or cost drivers before you're committed. Generally, early enough that structural and site realities inform design direction rather than chasing it later.

What's the difference between fixed-price and cost-plus when the build is complex?

While fixed-price transfers the risk of cost overruns to the builder (requiring a fully defined scope upfront), cost-plus offers more flexibility for changes during the build but requires you to carry the risk of price fluctuations. In complex projects, builders often blend them to balance predictability with flexibility.

What decisions must be locked early to avoid redesigns and delays?

Core structural and site-interaction decisions, specifically: where the house sits (siting), how high it sits (floor elevation), and the window package. These elements dictate the engineering and framing; changing them later requires unraveling the build process backwards.

How do HOAs and architectural review boards impact "impossible" designs?

They set material, height, setback, and aesthetic requirements that constrain—or sometimes enable—design choices. HOA/ARB standards can constrain massing and materials. Early engagement and confirmation prevents surprises and rework.

What's a practical first step if I'm still collecting inspiration?

Start with a simple vision statement and your top three non-negotiables. Then schedule a lot walk with a builder who asks questions before quoting, or run the feasibility checklist above to identify missing feasibility inputs.

Purpose and Scope: This article explains how feasibility works in custom home building so readers can evaluate bold ideas with clarity. Examples are general; requirements and costs vary by site and jurisdiction.

Disclaimer: This article is for general informational purposes only and does not constitute engineering, legal, permitting, or financial advice. Requirements vary by jurisdiction and by site conditions. Consult qualified professionals and the appropriate local authorities for project-specific guidance.

Our Editorial Process: Our expert team uses AI tools to help with research and drafting, with expert humans on our Insights Team to ensure accuracy and clarity.

By Riverbend Homes

Riverbend Homes is a Texas Hill Country design-build firm based in Spicewood, focused on guiding clients through a clear feasibility-to-build process for high-trust custom homes. Riverbend is a member of the Texas Association of Builders.